- Humidity-independent hydrogen concentration measurement with thermal conductivity.

- Quantitative hydrogen purity measurement with TC

- Suitable for use up to 700 bara

- Ideal for electrolysis monitoring

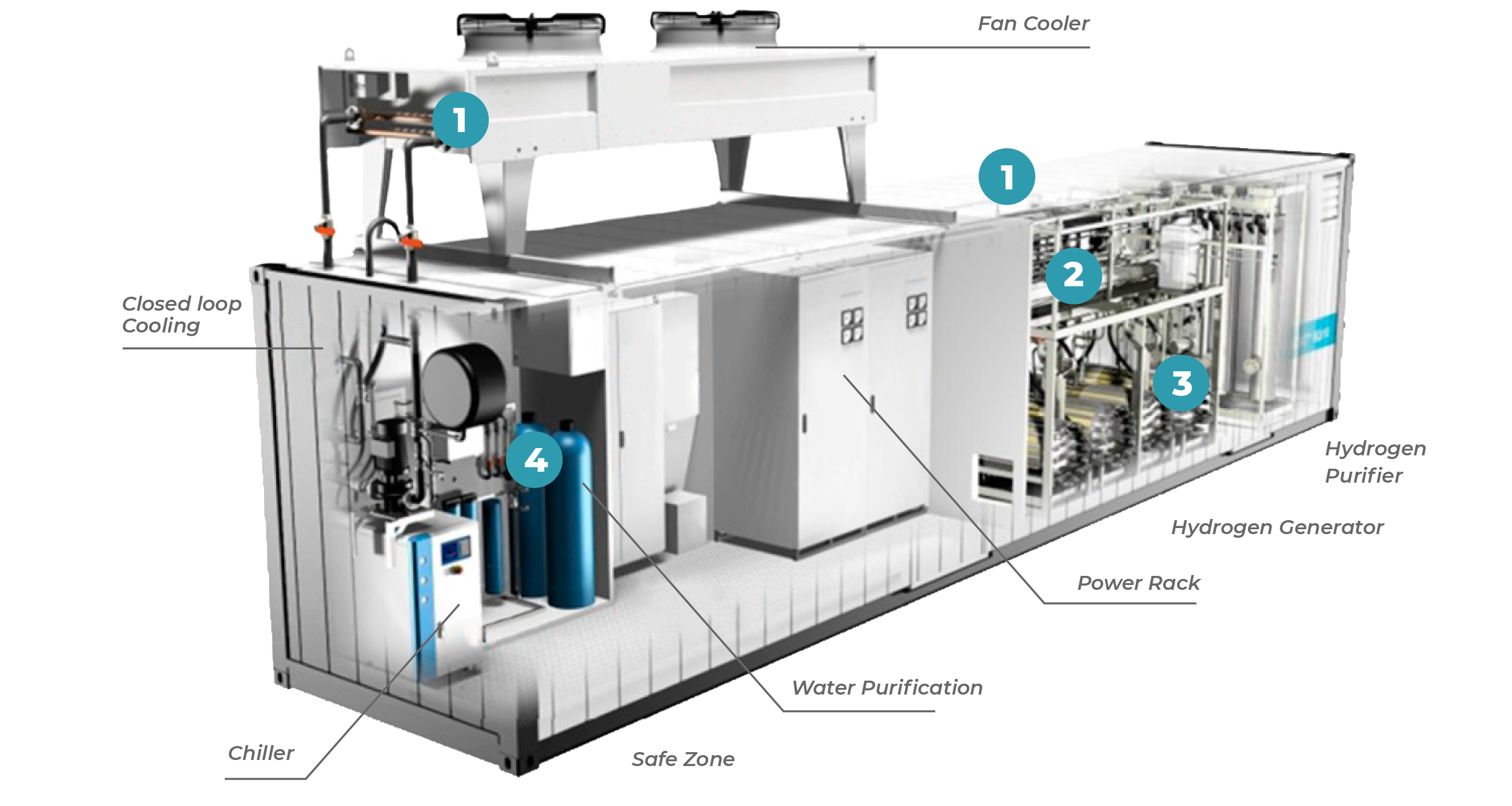

GAS ANALYSIS IN ELECTROLYSIS

(Proton exchange membrane)

(High pressure electrolysis)

(Alkaline electrolysis)

Hydrogen analysis, measurement and monitoring

Hydrogen analysis can be performed on different measurement technologies. The different measuring methods have their advantages and disadvantages. The Archigas measuring instruments can be used for all measuring tasks in an electrolyzer due to specially developed microsensors and different designs.

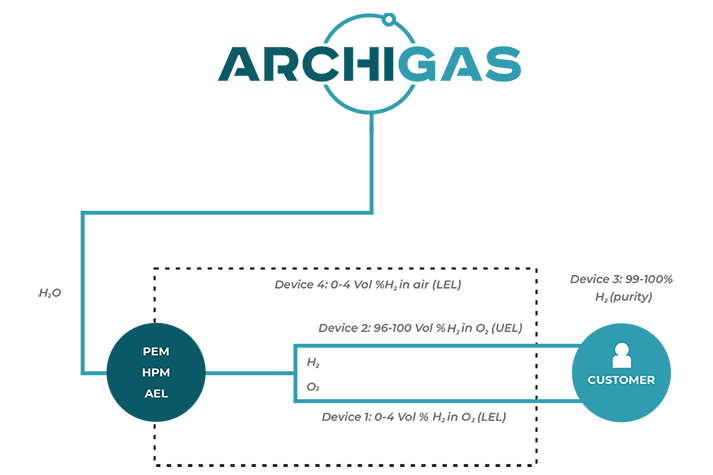

Lower and upper explosion limit (LEL, UEL)

The lower and upper explosion limits enclose the range of explosive mixtures, i.e. the range of the content of flammable substance in the mixture with an oxidizing agent in which an explosion can occur. Lower explosion limit 4.0% by volume (mol%) Upper explosion limit 77.0% by volume (mol-%)

Hydrogen quality with thermal conductivity

Quality measurement of hydrogen is necessary for the entire industry. Continuous online quality measurement enables process monitoring and delivery of high quality hydrogen to the customer. With Archigas equipment the H2 purity can be checked continuously and online up to 5.0

Leak detection and room air monitoring

If a leak occurs in the manufacturing process, hydrogen escapes into the environment. In closed rooms, an explosive mixture can develop. The hydrogen concentration in the room air is monitored. Lower explosion limit 4.0% by volume (vol%)

REQUEST FOR A TEST TODAY

Challenges

Challenges for H2 measurement in electrolyzers:

- Humidity in the process gas falsifies measurements with thermal conductivity

- Cross-sensitivity compensation or dehumidification of the gas is required

- The reaction times (t90) should be kept low in the process require complex sample preparation

- Some processes receive corrosive gases

- High operating pressures and process temperature require additional sample preparation

Advantages Archigas devices

Advantages of the TCD3000 for H2 measurement in electrolysers:

- Humidity-independent measurement with thermal conductivity.

- Short response times of less than one second.

- Pressures up to 200 bara are permissible.

- Corrosion resistance.

- Continuous online quality monitoring up to H2 5.0 possible.

- Process gas temperatures up to 100°C possible.

- No additional costly equipment needed for quality measurement.

- Reasonable price.

Download datasheet

Download datasheet