Hydrogen Production

Fuel Cell Applications

Hydrogen in Natural Gas

Process Analysis

Customized Solutions

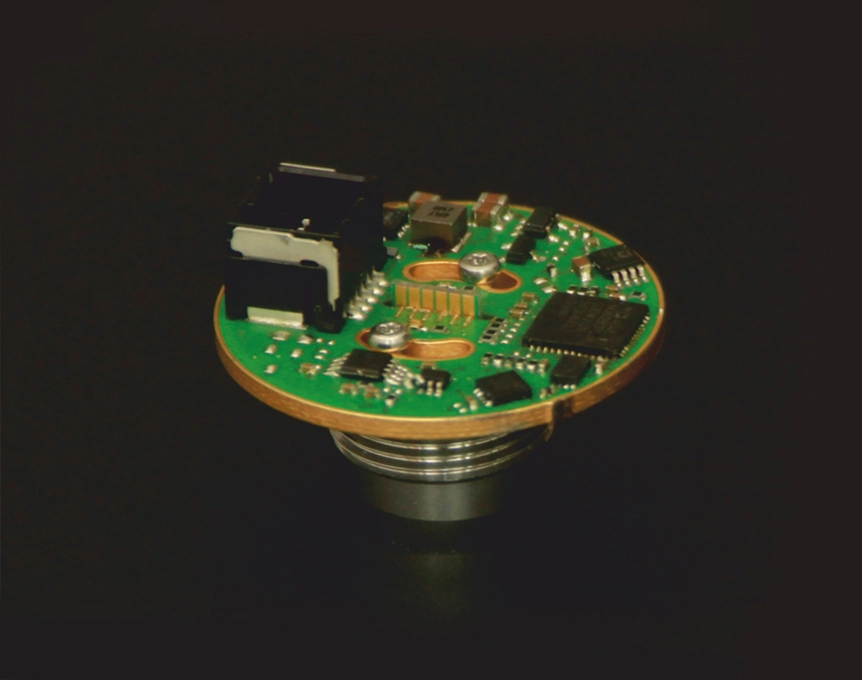

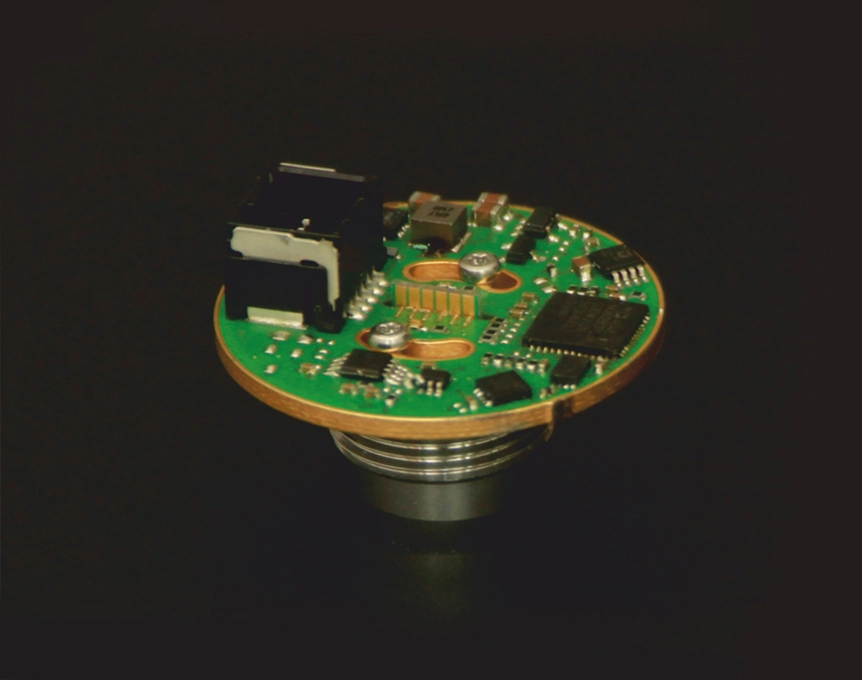

The compact and robust transmitter TCD3000 is recommended for precise, fast and sensitive measurement of (quasi-) binary gas mixtures.

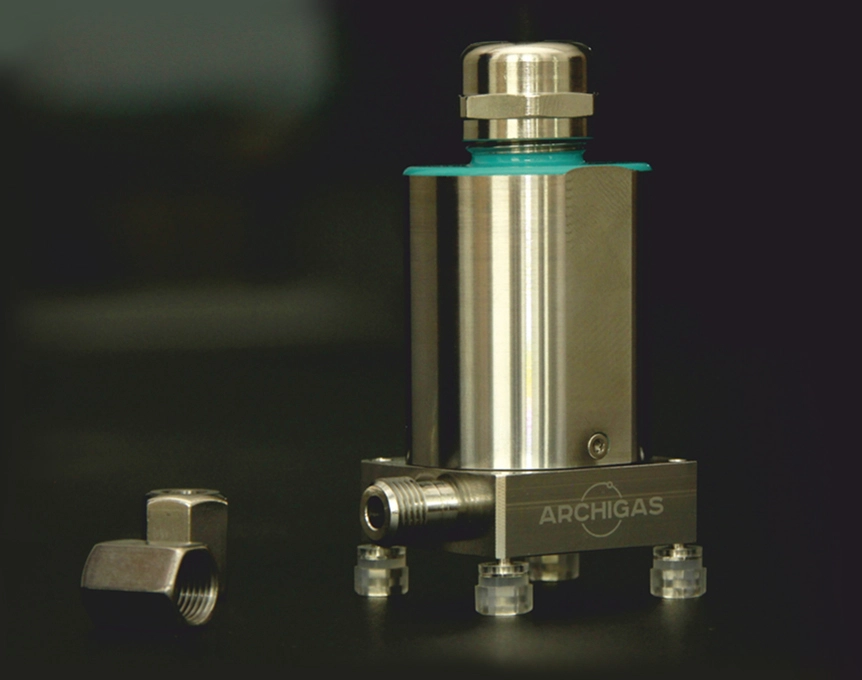

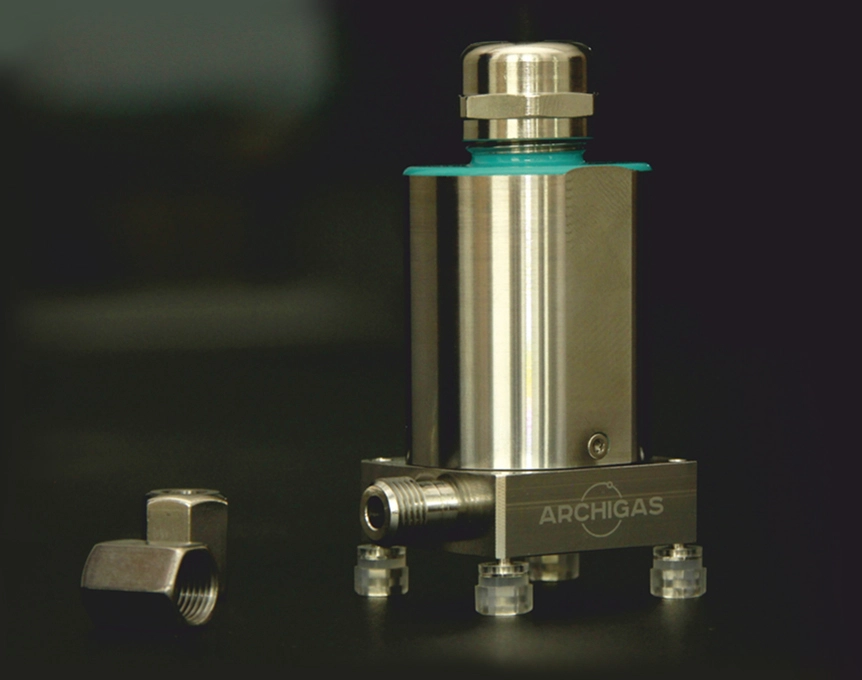

Due to the stainless-steel housing and the IP67 protection class, the unit can be used safely in harsh environments.

The unit is completely equipped with metal-to-metal connections, so that a high degree of tightness and pressure resistance over 200 bars can be guaranteed.

The gas-carrying parts and the sensor are corrosion-resistant:

The gas path is made of high-grade stainless steel 1.4404,

The sensor on the gas side is completely glazed.

In addition, the sensor is protected against condensation and dust.

The internal memory can store the curves for up to 99 gas pairs, so that the device can be easily adapted to changing measurement requirements.

The unit is connected to the process via axial pneumatic connections M10. Such a system makes assembly and disassembly in existing installations easier.

At the customer’s request, the wide range of adapters is available.

| SPECIFICATION | |

|---|---|

| Dimensions with connectors; weight | B=54 mm, H=80 mm, D=34 mm; ~500g |

| Power supply | 12-36 VDC, 24 W |

| Digital Output | RS485 or TTL Baud rate 19200/ Data 8bit |

| Analog Output | 4-20 mA, 3-wire connection |

| Ambient temperature range | -10 °C to 50 °C |

| Warm up time Approx. lOmin | Approx. 10 min |

| Flow rate | 10 l/h-120 l/h |

| 90-time | < 1s |

| Noise | < 0,5 ppm |

| Drift at zero point | < 50 ppm per week |

| Repeatability | < 50 ppm |

| Error due to change of ambient temperature | < 50 ppm per 10 °C |

| Error due to change of flow at 70 1/h | < 50 ppm per 10 l/h |

| Gas pressure (absolute) | 0,8 – 200 bara / 700 bara on request |

| Error due to change of pressure (above 800h Pa) | < 50 ppm per 10 hPa |

The measurement of hydrogen concentration using thermal conductivity offers several advantages

- Firstly, it enables a fast and accurate determination of hydrogen content in a medium. By utilizing thermal conductivity, precise measurements can be obtained without the need for complex and time-consuming sampling or chemical analyses.

- Secondly, it enables a fast response time of just 100 ms, allowing for nearly real-time monitoring. This enables quick detection of changes in hydrogen concentration and early identification of potential safety risks.

- Thirdly, thermal conductivity measurement is a cost-effective solution. The required sensors and devices are typically affordable and easy to operate. Additionally, the method does not require expensive consumables or extensive maintenance.

- Fourthly, thermal conductivity measurement provides a wide dynamic measurement range. It can detect hydrogen concentrations ranging from a few parts per million (ppm) to 100% volume percent (Vol%). This versatility allows for its application in a variety of scenarios, from monitoring hydrogen leaks in industrial facilities to accurately determining hydrogen concentration in fuel cells.

- Finally, measuring hydrogen concentration through thermal conductivity allows for continuous monitoring. By employing automated systems, continuous measurements can be performed to capture real-time changes and detect potential safety risks early on.

- Overall, the measurement of hydrogen concentration using thermal conductivity provides an efficient, accurate, non-contact, and cost-effective method for monitoring hydrogen in various applications, including industry, energy systems, and environmental protection.

MEASUREMENT RANGES FOR BINARY GASES

| Measuring Gas | Carrier Gas | Basis Range | Smallest Range |

|---|---|---|---|

| Hydrogen (H2) | Nitrogen (N2) or Air | 0%-100% | 0%-0.2% |

| Oxygen (O2) | Nitrogen (N2) | 0% – 100% | 0% – 15% |

| Helium (He) | Nitrogen (N2) or Air | 0% – 100% | 0% – 0.8% |

| Carbon dioxide (CO2) | Nitrogen (N2) or Air | 0% – 100% | 0% – 3% |

| Nitrogen (N2) | Argon (Ar) | 0% – 100% | 0% – 3% |

| Oxygen (O2) | Argon (Ar) | 0% – 100% | 0% – 2% |

| Hydrogen (H2) | Argon (Ar) | 0% – 100% | 0% – 0.1% |

| Helium (He) | Argon (Ar) | 0% – 100% | 0% – 0.5% |

| Carbon dioxide (CO2) | Argon (Ar) | 0% – 60% | 0% – 10% |

| Argon (Ar) | Carbon dioxide (CO2) | 40% – 100% | – |

| Methane (CH4) | Nitrogen (N2) or Air | 0% – 100% | 0% – 2% |

| Methane (CH4) | Argon (Ar) | 0% – 100% | 0% – 1.5% |

| Argon (Ar) | Oxygen (O2) | 0% – 100% | 0% – 3% |

| Measuring Gas | Carrier Gas | Basis Range | Smallest Range |

|---|---|---|---|

| Nitrogen (N2) | Hydrogen (H2) | 0% – 100% | 0% – 2% |

| Oxygen (O2) | Carbon dioxide (CO2) | 0% – 100% | 0% – 3% |

| Hydrogen (H2) | Helium (He) | 20% – 100% | – |

| Hydrogen (H2) | Methane (CH4) | 0% – 100% | 0% – 0.5% |

| Hydrogen (H2) | Carbon dioxide (CO2) | 0% – 100% | 0% – 0.5% |

| Sulfur hexafluoride (SF6) | Nitrogen (N2) or Air | 0% – 100% | 0% – 2% |

| Nitrogen dioxide (NO2) | Nitrogen (N2) | 0% – 100% | 0% – 5% |

| Hydrogen (H2) | Oxygen (O2) | 0% – 100% | 0% – 0.2% |

| Argon (Ar) | Xenon (Xe) | 0% – 100% | 0% – 3% |

| Neon (Ne) | Argon (Ar) | 0% – 100% | 0% – 1.5% |

| Krypton (Kr) | Argon (Ar) | 0% – 100% | 0% – 2% |

| Extinguishing gas (R125) | Nitrogen (N2) or Air | 0% – 100% | 0% – 5% |

| Deuterium (D2) | Nitrogen (N2) or Air | 0% – 100% | 0% – 0.5% |

| Deuterium (D2) | Helium (He) | 0% – 100% | 0% – 5% |

H2

INFORMATION

For any further questions or quotes please do not hesitate to contact us using the contact form or contact information below.

When submitting the data entered in the contact form by clicking on the button below, you declare that you have read the privacy policy and that you agree that the data provided will be collected and stored electronically.

The data is used only strictly earmarked for processing and answering your request. By submitting the contact form you agree to the processing. You may revoke your consent at any time with future effect. In case of cancellation your data will be deleted immediately.

CONTACT US

Download datasheet

Download datasheet