APPLICATIONS

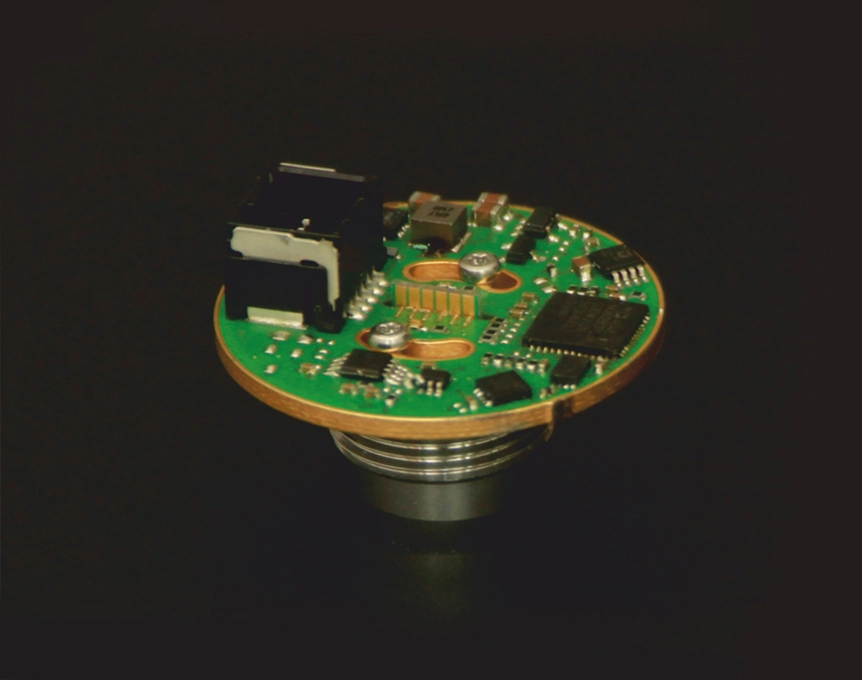

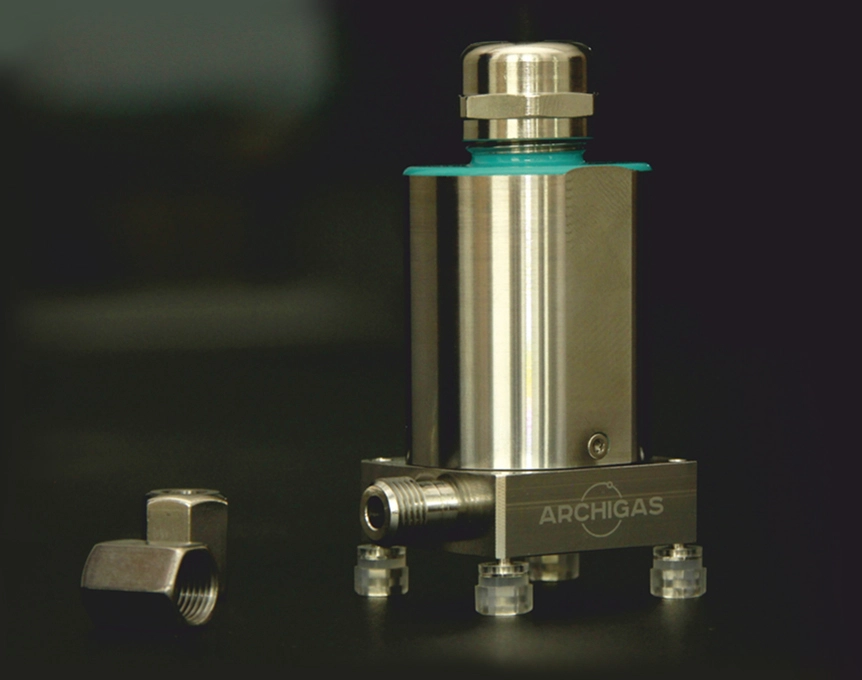

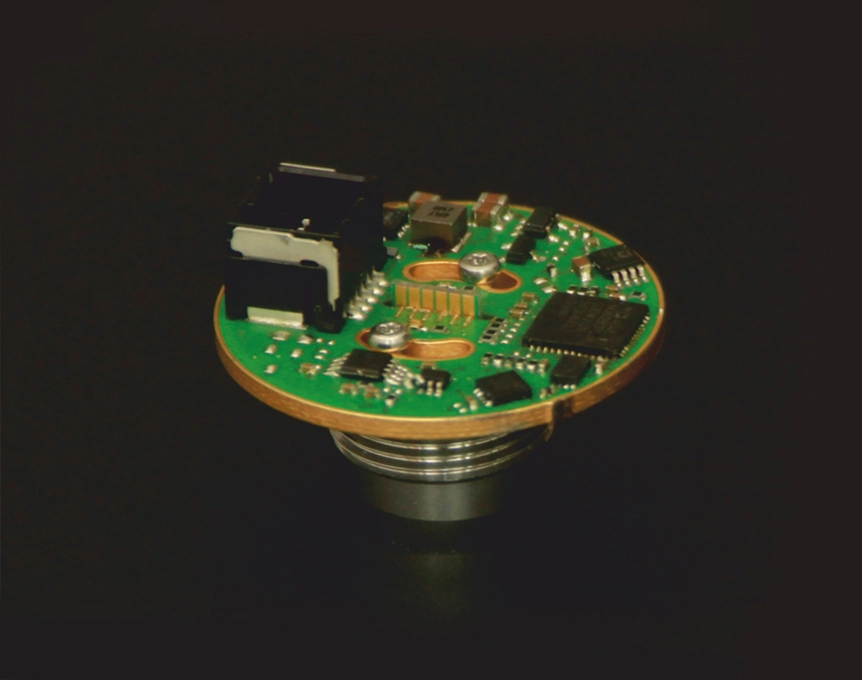

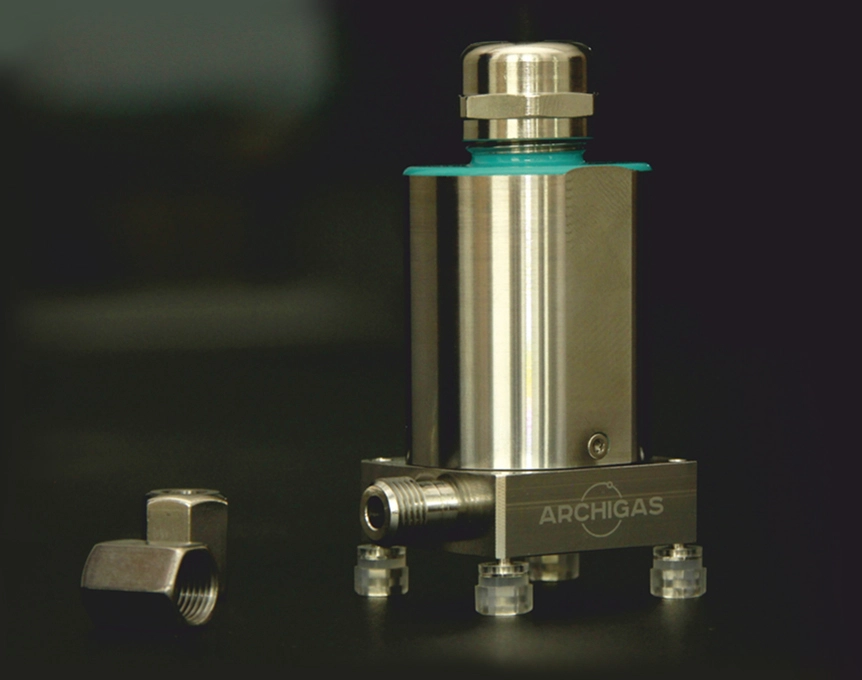

Customized Adaptations of OEM Devices for Precise Gas Measurements Based on Thermal Conductivity

When measuring gases in challenging environments, accurate and reliable results are of utmost importance. OEM gas measurement devices with customized adaptations offer an outstanding solution to meet specific requirements in various applications. Particularly based on thermal conductivity, these devices enable precise measurements of gases such as hydrogen, which are commonly used in gas chromatographs, biogas measurement systems, and syngas measurement systems.

Customized adaptations for precise gas measurements: OEM gas measurement devices are developed in close collaboration with customers to meet their individual requirements. An important feature of these devices is their ability to utilize thermal conductivity to perform accurate measurements. By precisely detecting thermal changes, these devices can deliver high-quality measurement results.

| SPECIFICATION | |

|---|---|

| Dimensions with connectors; weight | B=54 mm, H=80 mm, D=34 mm; ~500g |

| Power supply | 12-36 VDC, 24 W |

| Digital Output | RS485 or TTL Baud rate 19200/ Data 8bit |

| Analog Output | 4-20 mA, 3-wire connection |

| Ambient temperature range | -10 °C to 50 °C |

| Warm up time Approx. lOmin | Approx. 10 min |

| Flow rate | 10 l/h-120 l/h |

| 90-time | < 1s |

| Noise | < 0,5 ppm |

| Drift at zero point | < 50 ppm per week |

| Repeatability | < 50 ppm |

| Error due to change of ambient temperature | < 50 ppm per 10 °C |

| Error due to change of flow at 70 1/h | < 50 ppm per 10 l/h |

| Gas pressure (absolute) | 0,8 – 200 bara / 700 bara on request |

| Error due to change of pressure (above 800h Pa) | < 50 ppm per 10 hPa |

Application Areas:

Gas Chromatographs:

OEM gas measurement devices find application in gas chromatographs to analyze various gases accurately. By measuring thermal conductivity, these devices can determine the concentration of hydrogen gases in the sample. This technology allows for the precise separation and identification of compounds, which is crucial for applications in chemistry, petrochemistry, and environmental analysis.

Biogas Measurement Systems:

OEM gas measurement devices play a vital role in biogas production and utilization. By accurately measuring thermal conductivity, these devices can detect the hydrogen content in biogas. This is essential as hydrogen serves as an indicator for the optimal operation of biogas plants. The precise measurements contribute to monitoring and controlling biogas processes.

Syngas Measurement Systems:

In syngas production, particularly during the conversion of coal or biomass into syngas, OEM gas measurement devices with thermal conductivity measurement enable reliable monitoring of the hydrogen content in syngas. This ensures efficient operation of the facilities and optimal production conditions for further processing.

Advantages of Hydrogen Detection Technology:

The utilization of thermal conductivity for hydrogen detection offers several advantages. Firstly, hydrogen is a highly flammable gas, and its accurate monitoring is crucial for minimizing safety risks. OEM gas measurement devices with thermal conductivity measurement provide a reliable method for hydrogen detection. Secondly, the precise measurement of thermal conductivity allows for accurate determination of hydrogen content in various gas mixtures, which is essential for effective process control and quality assurance.

Conclusion:

Customized adaptations of OEM gas measurement devices based on thermal conductivity provide a reliable and precise solution for gas measurement, particularly for hydrogen detection. These devices find application in gas chromatographs, biogas measurement systems, and syngas measurement systems, contributing to safety, process optimization, and quality assurance in various industries. Collaborating with an OEM manufacturer enables customers to obtain tailored solutions that meet their specific requirements while ensuring the highest measurement accuracy and reliability.

INFORMATION

For any further questions or quotes please do not hesitate to contact us using the contact form or contact information below.

When submitting the data entered in the contact form by clicking on the button below, you declare that you have read the privacy policy and that you agree that the data provided will be collected and stored electronically.

The data is used only strictly earmarked for processing and answering your request. By submitting the contact form you agree to the processing. You may revoke your consent at any time with future effect. In case of cancellation your data will be deleted immediately.

CONTACT US

Download datasheet

Download datasheet